MBR membrane assembly

Membrane element construction

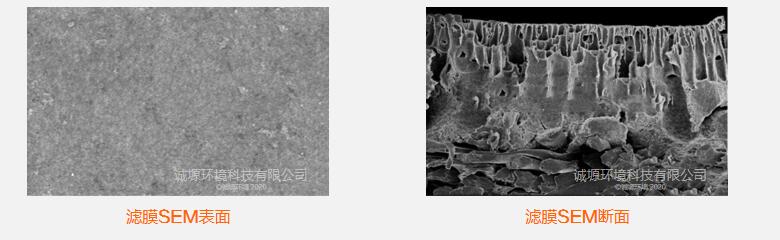

Chengyuan series The flat membrane element mainly includes support plate (ABS material), membrane lining and filter membrane. The filter membrane is welded on both sides of the support plate by ultrasonic welding, and the water to be treated is taken out from the water outlet after passing through the membrane and the membrane lining.

Advantages of MBR flat membrane technology

A、 The material of flat filter membrane is polyvinylidene fluoride (PVDF), which has good chemical stability and mechanical properties.

B、 The average pore diameter of flat membrane is Zero point one μ m is the reliable guarantee of high quality effluent of MBR system。

C、 The water collecting flume inside the supporting plate designed by professional technology can ensure the low energy consumption and high efficiency water production of MBR system.

Process characteristics of MBR flat membrane

It can intercept all suspended solids and colloids. Membrane separation increases the concentration of activated sludge in the aeration tank, increases the rate of biodegradation, and reduces the discharge of residual sludge.

It has good strength, no broken wire, high reliability of effluent water quality, large flux and low requirement for wastewater pretreatment. Impact load resistance, good pollution resistance, convenient maintenance and management.

The flat membrane can remove the pollutants attached to the membrane surface by using the scouring effect of aeration on the membrane surface, so as to maintain a high membrane flux, and the water conservancy conditions are easy to control.

Membrane element construction

Polyvinylidene fluoride (PVDF) is a new membrane material with excellent comprehensive performance. It has high mechanical strength, acid and alkali resistance and chemical stability. It has outstanding dielectric, biocompatibility, heat resistance, high separation accuracy and high efficiency. It has been widely used in membrane separation View.

Strict production process control ensures that the ultrafiltration membrane has typical asymmetric structure and stable mechanical strength, so as to ensure that the ultrafiltration membrane has excellent pollution resistance and integrity.

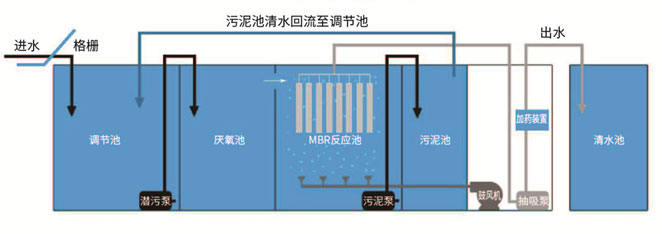

Introduction of membrane bioreactor (MBR)

Membrane bio reactor (MBR) is a new type of wastewater treatment system which combines membrane separation technology and biological treatment technology. Membrane module is used to replace the secondary sedimentation tank at the end of traditional biological treatment technology, to maintain high activated sludge concentration in the bioreactor, improve the organic load of biological treatment, so as to reduce the occupied area of sewage treatment facilities, and reduce the excess sludge by maintaining low sludge load. The main use of membrane separation equipment to intercept activated sludge and macromolecular organics in water. In the membrane bioreactor system, the concentration of MLSS can be increased to 8000-10000mg / L, or even higher; the sludge age (SRT) can be extended to more than 30 days.

Membrane bioreactor can retain microorganisms with long generation cycle due to its effective retention effect, and realize the deep purification of sewage. Meanwhile, nitrifying bacteria can fully reproduce in the system, and its nitrification effect is obvious, which provides the possibility for deep phosphorus and nitrogen removal.

MBR is an efficient combination of membrane separation technology and biological treatment. Its origin is to replace the secondary sedimentation tank in activated sludge process with membrane separation technology for solid-liquid separation. This process not only effectively achieves the purpose of mud water separation, but also has the incomparable advantages of the traditional three-stage sewage treatment process:

1、Efficient solid-liquid separation, the separation effect is far better than the traditional sedimentation tank, the effluent water quality is good, the suspended solids and turbidity of the effluent are close to zero, which can be reused directly, realizing the sewage resource.

2、The high efficiency of the membrane can make the microorganism completely trapped in the bioreactor, realize the complete separation of HRT and SRT, and make the operation control flexible and stable.

3、Because MBR combines the aeration tank and secondary sedimentation tank of traditional sewage treatment into one, and replaces all the process facilities of three-stage treatment, it can greatly reduce the floor area and save the civil construction investment.

4、It is beneficial to the retention and reproduction of nitrifying bacteria, and the nitrification efficiency of the system is high. Through the change of operation mode, it can also have the function of deamination and dephosphorization.

5、Because mud age can be very long, the degradation efficiency of refractory organics can be greatly improved.

6、When the reactor operates under high volume load, low sludge load and long sludge age, the excess sludge output is very low. Because the sludge age can be infinitely long, theoretically zero sludge discharge can be realized.

7、The system realizes PLC control and convenient operation and management

Performance parameters of membrane element